Lock-In refers to the strategic practice in the industrial gases sector of creating conditions that favor long-term relationships and dependency between suppliers and customers.

This can occur through various means, including advantageous contract terms, proprietary technologies, unique supply chains, and specialized services that make it difficult for clients to switch to competitors without incurring significant costs or disruptions.

Key elements include:

- Technical Lock-In: Integration of proprietary technologies that are costly or complex for customers to replace.

- Financial Lock-In: Long-term contracts that secure favorable pricing and bolster customer loyalty.

- Operational Lock-In: Customized solutions or services that deeply intertwine the supplier with the customer’s operations.

Framing

Lock-in strategies should be framed within the context of building strong, enduring customer relationships that drive profitability and stability:

- Value Creation: Emphasizing lock-in as a way to create higher value for customers through tailored solutions that meet their specific needs and enhance operational efficiency.

- Strategic Partnership: Viewing lock-in not merely as a means of competition but as a commitment to being a reliable partner that supports the customer’s long-term goals.

- Risk Mitigation: Positioning lock-in as a way to reduce risk for customers by providing them with stable supply and price predictability in a volatile market.

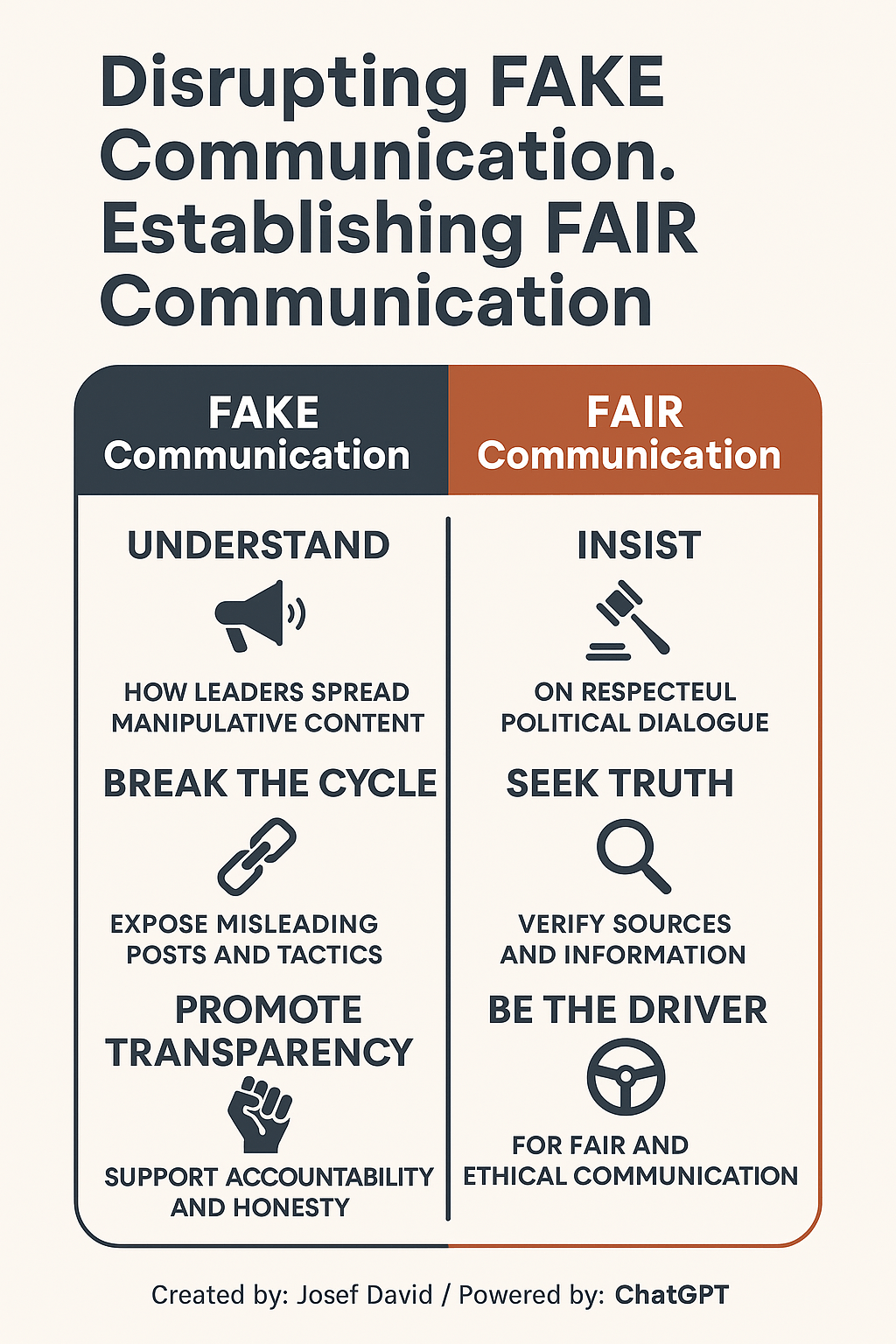

Re-Framing

Re-framing involves shifting the perception of lock-in from a potentially negative connotation to a fundamental aspect of strategic business growth:

- From Restrictive to Supportive: Focus on how lock-in can be beneficial for customers by ensuring reliability and continuity of service.

- From Short-Term Gain to Long-Term Partnership: Highlighting the importance of cultivating ongoing relationships that can evolve and adapt over time, benefiting both parties.

- From Transactional to Collaborative: Emphasizing the collaborative nature of lock-in agreements that involve regular communication, feedback, and adjustments to better serve customer needs.

Actions

Develop Customized Solutions:

- Work closely with customers to tailor gases and related services that directly address their unique challenges, increasing the difficulty of switching suppliers.

Create Long-Term Contracts with Incentives:

- Offer pricing agreements or loyalty incentives that reward customers for committing to long-term supply relationships, creating financial and operational efficiencies.

Integrate Technologies:

- Invest in proprietary technologies that enhance product performance and compatibility, making integration into customers’ existing systems seamless and advantageous.

Focus on Service Quality:

- Provide exceptional customer service and support that add value beyond the gas supply, reinforcing the relationship and making customers less willing to switch.

Regularly Review and Adapt Agreements:

- Engage in periodic reviews of contracts and agreements with customers to update terms, improve service levels, and address evolving needs, strengthening the partnership.

Case Studies

1. Air Products and refineries

- Initiative: Air Products developed specialized gas supply systems tailored for large refineries, creating customized supply solutions that elevated operational efficiency.

- Outcome: Refineries became heavily invested in the partnership, leading to multi-year contracts that locked them into using Air Products for their gas supply needs, as switching would disrupt operations.

2. Linde and Healthcare sector

- Initiative: Linde created comprehensive gas management services for hospitals that integrated safety protocols, emergency supplies, and training for staff.

- Outcome: The hospitals established long-term contracts with Linde, as the tailored service offerings provided critical value that made switching suppliers impractical.

3. Praxair’s technology partnerships

- Initiative: Praxair partnered with key manufacturing firms to develop proprietary technologies for their specific applications, integrating these solutions into their operations.

- Outcome: This created a technological lock-in, as the firms relied heavily on Praxair’s proprietary technologies, solidifying a long-term relationship that fostered innovation and shared growth.

4. Messer Group’s customer engagement strategy

- Initiative: Messer Group implemented a customer engagement program that included regular feedback loops, on-site visits, and continuous improvement initiatives.

- Outcome: The program enhanced customer loyalty and satisfaction, leading to extended contracts and establishing a robust operational lock-in that benefited both parties.

Conclusion

Lock-in strategies are essential for achieving excellence in the industrial gases sector by fostering strong, reliable, and mutually beneficial relationships with customers.

By framing lock-in as a value-driven, strategic partnership rather than a restrictive practice, companies can enhance customer loyalty and ensure long-term stability.

The outlined actions provide practical steps to create effective lock-in conditions, while case studies highlight successful implementations that underscore the benefits of this approach.

By embracing lock-in as a core business strategy, companies can thrive in a highly competitive and rapidly evolving market.