Discover the industrial gas commercial rules that drive success in one hour

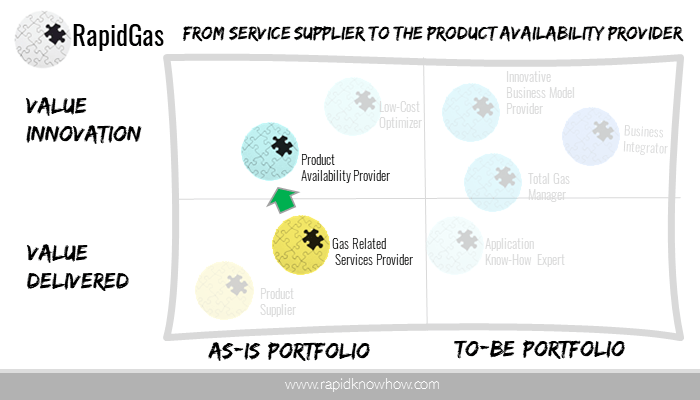

It is important to understand typical commercial practices within the industrial gases business, since these are common to all the leading players in the industry, especially in developed industrialised countries.

For the developing markets, even the major gas companies have to bow to local market conditions and practices initially, but eventually, a major player (or 2) will bring pricing discipline to the market.

We have therefore covered for this briefing the main commercial practices commonly observed in the industry.

I hope the industrial gas insight series will educate you to create value for all stakeholders.

Let’s start tomorrow negotiate on value and never again reduce prices . You have got the tools to succeed!

Promised? Thanks! It’s for the sake of the well-being of the industry and it’s people. Wish You All Success!

PIPELINE/ON-SITE SUPPLIES

PIPELINE/ON-SITE SUPPLIES

Pipeline or on-site supplies are individually negotiated between the gas company and the client.

This requires both an engineering and commercial input. The gas company needs to understand the customer’s demand pattern as well as purities, flow rates, pressures and other variables.

Besides pipeline supplies, back up liquid storage may also be required (on-site or by the gas company vaporising liquid on its premises to pressurise the pipeline).

There are invariably several engineering solutions, which can be considered to achieve an adequate continuity of supply. Also, there may be a need to supply specialist equipment for applying the gas in the customer’s process.

Supply scheme contracts are typically negotiated for 15 years supply (but sometimes shorter) to be able to recover the substantial capital investment in production and distribution plant at a reasonable unit price to the customer. Great care has to be exercised by the gas company to ensure that it obtains a worthwhile return over this long period as supply scheme contracts cannot be unilaterally re-negotiated. The tariff, therefore, has to be “indexed” for changing cost levels throughout the term.

Supply scheme tariffs can comprise several elements:

“facility” (or fixed) charge, usually invoiced as a lump sum each month.

This is to recover the fixed costs which are incurred for as long as the facilities are at the disposal of the customer (but not necessarily operating, such as during customer shutdown periods).

This facility charge usually includes an amount for obtaining the necessary financial return on the capital investment. It is usual for this charge to be at least partly indexed to a general cost inflation index so that the supply scheme profits are protected in real terms.

“primary” production charge, which is designed to recover the minimum operating costs incurred for holding the plant in a production state (normal situation), regardless of whether any gas is produced.

This is designed to recover the unavoidable semi-fixed operating costs (at maximum plant turn-down) during short-term cessation or reduction of supplies. This is usually a lump sum amount indexed to relevant cost indices such as for power and labour. It may change in a step-wise fashion if several plant items can be progressively switched off as output falls.

Unit unit gas charge (expressed as an amount per ton or cubic metre) for each gas supplied. There may be different gas charges for back-up liquids or gas obtained from liquid stocks than from gaseous product obtained directly from the production plant. These gas charges are designed to recover the variable operating costs, of which power and feed-stock costs are usually the main item but which can also include labour and maintenance costs. Gas charges are invariably indexed to the main input costs – power, feed-stock, labour.

BULK SUPPLIES

Bulk supplies normally entail some capital expenditure by the gas company to install its storage and pipeline systems on the customer’s premises and perhaps purchase specialised delivery vehicles. The gas companies usually prefer the equipment to be owned by themselves rather than the customer to discourage competitor’s access to the customer.

Given the infrastructure investment required, it is normal for gas companies to charge “rent” on a monthly basis for bulk supplies (and sometimes an up-front charge for unrecoverable expenditure related to specific equipment relevant to the customer’s particular application) and to have a contractual period of up to 5 years (maximum 3 years in the EU). Also there is a unit charge for the gas consumed, usually specific to a particular customer unless competition laws dictate otherwise. Prices are normally indexed to power costs and labour or general inflation index.

PACKAGED SUPPLIES

Since cylinders (compressed or liquid) are expensive relative to the value of gas they contain, it is essential for the gas companies to achieve tight control of their cylinder population and because cylinders are expensive assets, which are usually owned by the gas company, there is usually an understanding between the companies that they will not refill each other’s cylinders (in developed markets).

Gas companies need to have charging mechanisms, which recover a fair contribution to their cost and maintenance from each class of customer. Therefore they usually employ several “revenue streams” rather than having only a single all-inclusive unit price of gas, such as:

• cylinder deposits

• cylinder rentals

• transaction/admin. Charges

• gas charges

• delivery charges

The capital costs of cylinders can be recovered either through charging a returnable deposit for the cylinder or cylinder rent on a monthly or annual basis.

Cylinder deposits have the disadvantage that some customers may prefer to buy their own, and over the life of a cylinder (30 years or more) the initial deposit becomes negligible and of little motivation for the customer to return under-utilised cylinders.

However, in some countries where customers are difficult to trace, or there are difficulties with credit payments, this can be the best option.

Cylinder rentals are a more dynamic means of ensuring the customer does not hoard cylinders as he pays for each cylinder currently held.

As a pricing mechanism, they can also be easily changed with an immediate impact on revenues. It is not unusual for one-third of a gas company’s revenue from packaged gases to be from cylinder rentals.

In countries where order processing costs are high, a fixed charge per order is sometimes applied.

Gas prices (expressed as a cost of gas per cylinder and depending on cylinder size, or as a per cubic metre cost) can be kept low when “fixed costs” of cylinders and orders are being separately recovered.

This has the effect of favouring the large customer who orders in large lots and has a rapid turn-round of cylinders and therefore most closely mirrors the real cost of serving the customer (whether large or small). Delivery charges are often levied as some customers (especially small, local clients) prefer to collect from the gas company direct or from a depot.

It is usual for gas companies to have published “list” prices for these various elements of cylinder supplies which can be changed at will to reflect the current cost or competitive environment.

The gas companies often sell welding equipment and consumables alongside their cylinder gases to offer a “one-stop” shop for “gas and gear” to their welding customers. Such equipment may be manufactured by the gas company itself or merely traded.