Problem:

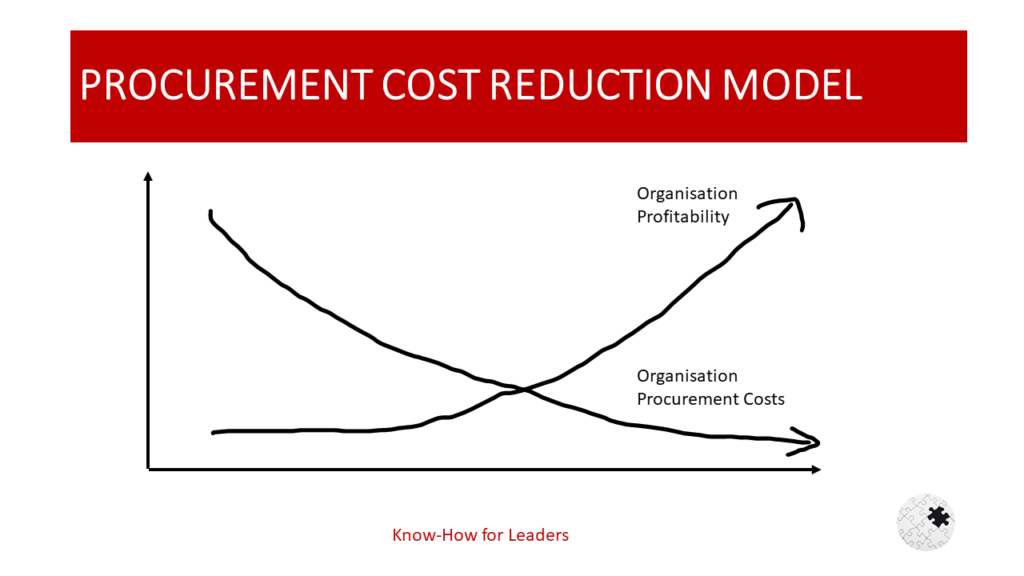

In today’s competitive business environment, procurement costs can significantly impact a company’s bottom line. Many organisations struggle with high procurement costs due to inefficient processes, lack of strategic sourcing, poor supplier management, and inadequate use of technology. These issues not only increase operational expenses but also hinder the company’s ability to deliver value to its customers.

Impact:

High procurement costs can have a detrimental effect on a company’s profitability and competitiveness. They can erode profit margins, reduce the company’s ability to invest in growth initiatives, and make it more difficult to compete on price with competitors. Furthermore, inefficient procurement processes can lead to delays in product delivery, which can damage customer relationships and harm the company’s reputation.

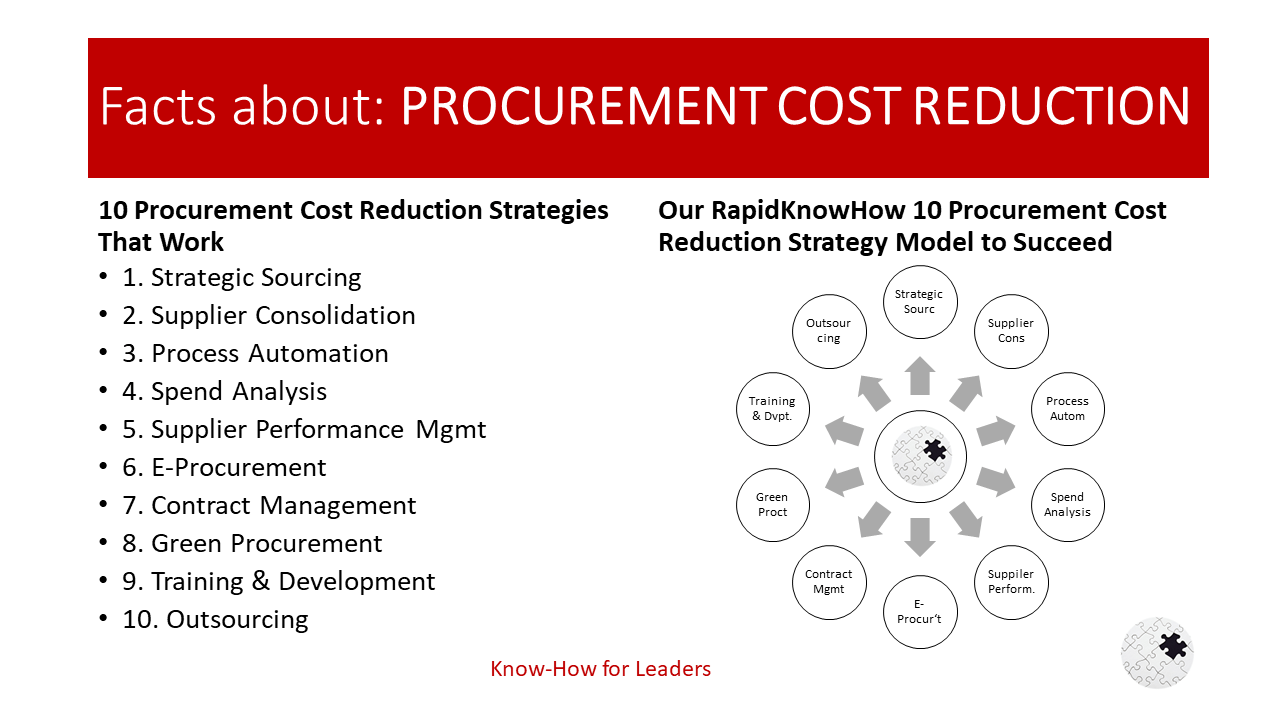

10 Rapid Procurement Cost Reduction Strategies:

1. Strategic Sourcing: This involves analysing the company’s spending patterns and identifying opportunities for cost savings through bulk purchasing or negotiating better terms with suppliers.

2. Supplier Consolidation: By reducing the number of suppliers, companies can achieve economies of scale and simplify their procurement processes.

3. Process Automation: Implementing procurement software can streamline processes, reduce errors, and free up staff time for more strategic tasks.

4. Spend Analysis: Regularly reviewing and analysing procurement data can help identify areas for cost reduction.

5. Supplier Performance Management: Regularly evaluating suppliers based on their performance can help ensure that they are delivering value for money.

6. E-Procurement: Using online platforms for procurement can reduce paperwork, speed up processes, and make it easier to compare prices from different suppliers.

7. Contract Management: Effective contract management can help avoid cost overruns and ensure that suppliers are meeting their contractual obligations.

8. Green Procurement: By choosing environmentally friendly products and suppliers, companies can reduce their environmental impact and potentially save money in the long term.

9. Training and Development: Investing in training for procurement staff can improve their skills and knowledge, leading to more effective procurement practices.

10. Outsourcing: For some companies, outsourcing procurement to a specialist provider can be a cost-effective solution.

Case Studies from Industry, Government, Retail:

Several organisations have successfully implemented these strategies to reduce their procurement costs. For example:

A leading manufacturing company achieved significant cost savings by consolidating its supplier base and implementing a strategic sourcing initiative.

Similarly, a government department reduced its procurement costs by automating its processes and implementing an e-procurement system.

In the retail sector, a major supermarket chain achieved cost savings through effective contract management and supplier performance management.

Get Started Step-by-Step:

1. Conduct a thorough analysis of your current procurement processes and identify areas for improvement.

2. Develop a procurement strategy that aligns with your company’s business objectives.

3. Implement the appropriate cost reduction strategies, such as strategic sourcing, supplier consolidation, or process automation.

4. Regularly review and analyse your procurement data to identify further opportunities for cost reduction.

5. Continually monitor and evaluate the performance of your suppliers to ensure they are delivering value for money.

6. Invest in training and development for your procurement staff to enhance their skills and knowledge.

7. Consider outsourcing your procurement activities if it is cost-effective for your company.

By following these steps, you can significantly reduce your procurement costs and improve your organization’s profitability and competitiveness.