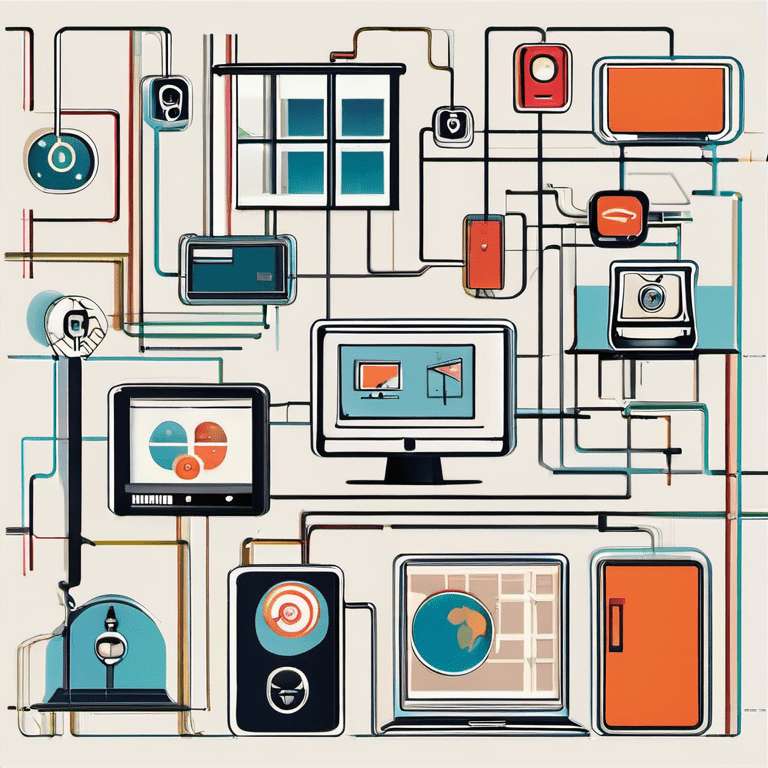

The Internet of Things (IoT) has been a buzzword in the tech industry for quite some time now. It refers to the network of physical devices, vehicles, appliances, and other items embedded with sensors, software, and network connectivity which enable these objects to connect and exchange data. In the context of industrial gases, IoT can be a game-changer. Let’s delve into this topic further.

**Need**

Industrial gases are critical to many industries including healthcare, food and beverage, electronics, energy, and more. Managing these gases efficiently is crucial for safety, cost-effectiveness, and environmental sustainability. However, traditional methods of managing industrial gases often involve manual processes that can be prone to errors and inefficiencies. This is where IoT comes in. By leveraging IoT technologies, companies can automate and optimize their industrial gas management processes.

**Solution**

IoT solutions for industrial gases typically involve the use of sensors and software to monitor gas levels in real-time. These sensors can be attached to gas cylinders or pipelines and connected to a central system via the internet. The system can then analyze the data collected by the sensors to provide insights on gas usage patterns, detect leaks or anomalies, predict when a gas cylinder is about to run out, among other things.

For instance, an IoT-enabled gas cylinder can send an alert to the central system when its level drops below a certain threshold. This allows companies to replace or refill the cylinder before it runs out completely, thus preventing any disruption in operations.

**Action**

Implementing an IoT solution for industrial gases involves several steps. First, companies need to identify their specific needs and challenges related to gas management. This could be anything from reducing gas wastage to improving safety measures.

Next, companies need to select appropriate IoT devices such as sensors and connectivity options that suit their specific needs. They also need to choose a suitable IoT platform that can collect and analyze data from these devices.

Once the IoT system is set up, companies need to train their staff on how to use it effectively. This includes understanding how to interpret the data provided by the system and how to respond to alerts or notifications.

**Profit**

The benefits of implementing an IoT solution for industrial gases are manifold. Firstly, it can significantly reduce wastage by ensuring that gas cylinders are replaced or refilled on time. This can result in substantial cost savings.

Secondly, it can improve safety by enabling real-time monitoring of gas levels and early detection of leaks or anomalies. This can prevent accidents and protect employees’ health.

Thirdly, it can enhance operational efficiency by automating manual processes and providing actionable insights on gas usage patterns. This can help companies optimize their operations and make more informed decisions.

**Conclusion**

In conclusion, cracking the IoT code for industrial gases involves understanding the specific needs and challenges of your company, selecting appropriate IoT technologies, setting up an effective IoT system, and training your staff on how to use it. The benefits of doing so can be significant, including cost savings, improved safety, and enhanced operational efficiency. As such, it’s worth considering for any company that uses industrial gases in its operations.