Cracking the Palletizing Ecosystem Code

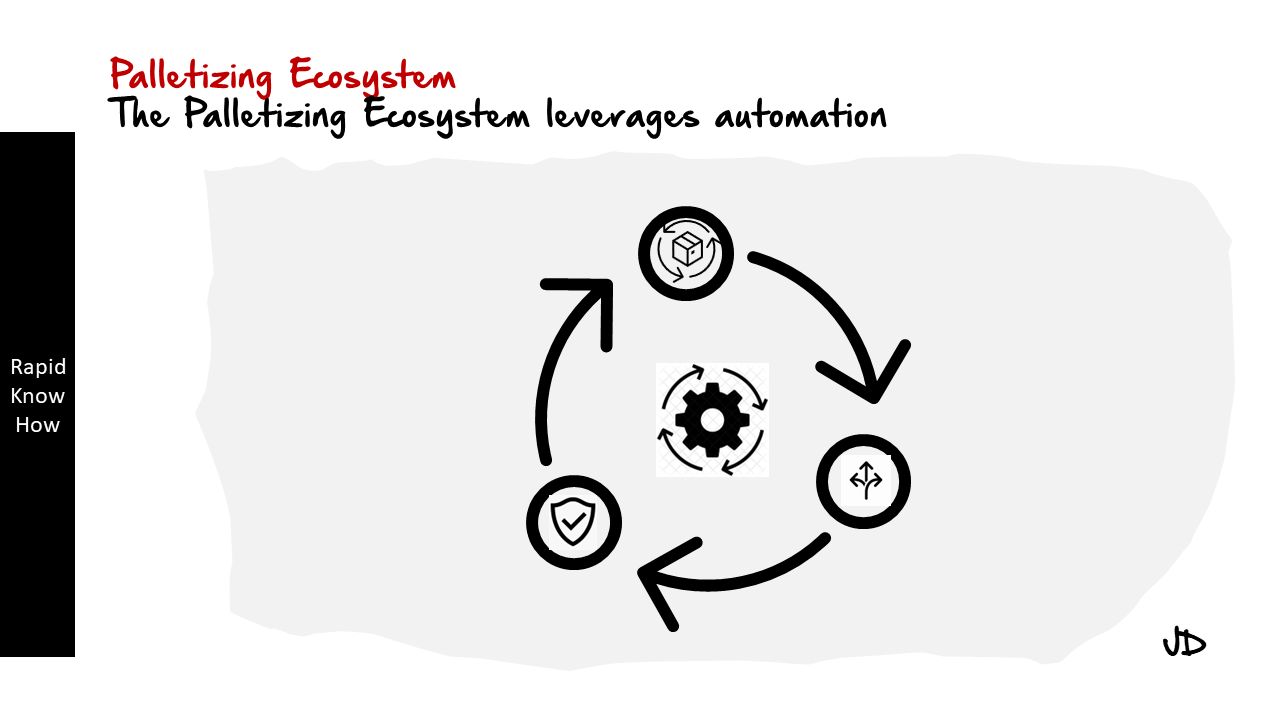

Palletizing, a critical process in the logistics and supply chain industry, involves the stacking of goods or products onto a pallet. The palletizing ecosystem is a complex network of processes, technologies, and stakeholders that work together to ensure efficient and effective palletizing. Cracking this ecosystem code requires an understanding of its design, operation, and strategic advantages.

Design of the Best-in-Class Palletizing Ecosystem

The best-in-class palletizing ecosystem is designed with a focus on efficiency, flexibility, and safety. It incorporates advanced technologies such as robotics, automation, and artificial intelligence to streamline operations and reduce manual labor.

At the heart of this ecosystem is the palletizing machine or robot. These machines are designed to handle a wide range of products with varying shapes, sizes, and weights. They are equipped with advanced sensors for precise positioning and movement control. Some machines also feature machine learning capabilities that allow them to adapt to different product types and packaging configurations.

The ecosystem also includes conveyor systems for transporting products to and from the palletizing area. These systems are designed for smooth and efficient movement of goods, minimizing product damage and ensuring timely delivery.

In addition to hardware components, the best-in-class palletizing ecosystem also includes software solutions for managing operations. These solutions provide real-time visibility into operations, enabling proactive decision-making and optimization of resources.

Operation of the Best-in-Class Palletizing Ecosystem

The operation of the best-in-class palletizing ecosystem is characterized by high levels of automation and integration. Products arriving at the palletizing area are automatically identified using barcode scanners or RFID readers. The information is then used to determine the appropriate stacking pattern based on product type, size, weight, and other factors.

The products are then transported to the palletizing machine via conveyor systems. The machine picks up each product using its robotic arm or gripper, places it on the pallet according to the predetermined stacking pattern, and repeats this process until the pallet is fully loaded.

Once a pallet is complete, it’s automatically moved out of the palletizing area for wrapping or strapping before being transported to its final destination. Throughout this process, data is continuously collected and analyzed to monitor performance and identify opportunities for improvement.

Strategic Advantage of the Best-in-Class Palletizing Ecosystem

The strategic advantage of a best-in-class palletizing ecosystem lies in its ability to enhance operational efficiency while reducing costs. By automating manual tasks, it reduces labor costs and minimizes human error. It also increases throughput by enabling continuous operation without breaks or downtime.

Moreover, by integrating different components into a single system, it simplifies management and control of operations. This integration also facilitates data sharing across different stages of the process, providing valuable insights for decision-making.

Furthermore, by incorporating advanced technologies such as robotics and AI, it enhances flexibility and adaptability. This allows companies to easily adjust their operations in response to changes in demand or product mix.

In conclusion, cracking the code of the palletizing ecosystem involves understanding its design principles centered around efficiency, flexibility, safety; its operational mechanisms that leverage automation; and its strategic advantages that contribute towards cost reduction while enhancing productivity. By doing so businesses can optimize their logistics processes leading towards improved profitability.