The Digitalised Pallet System: An Overview

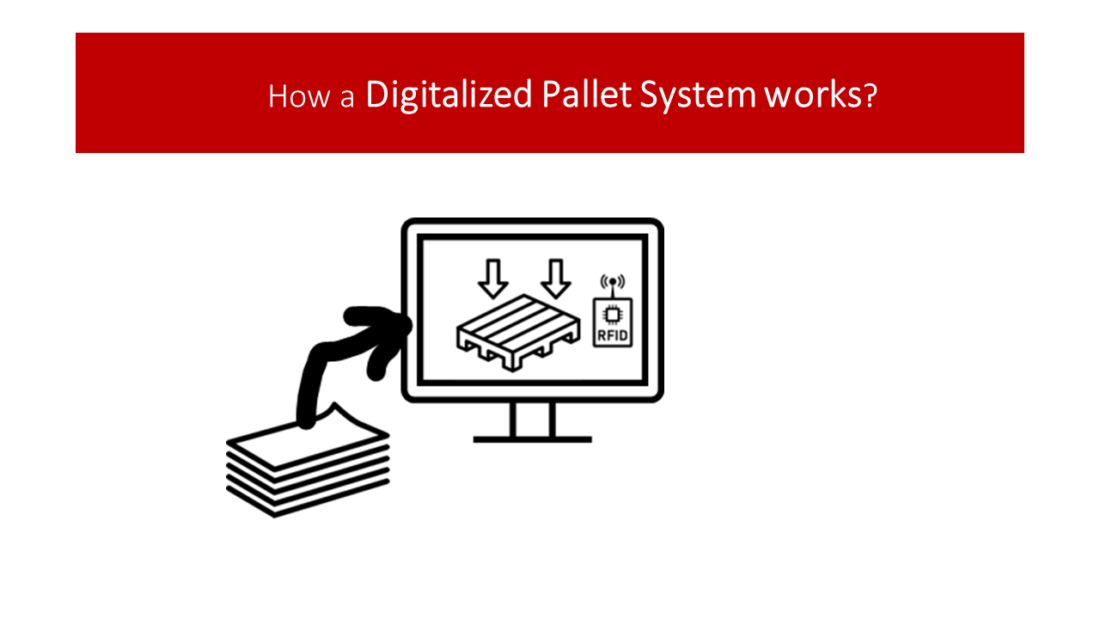

A digitalised pallet system is a technologically advanced method of managing and tracking the movement of goods in a warehouse or distribution centre. This system utilises digital technology, such as RFID (Radio Frequency Identification) tags, IoT (Internet of Things) devices, and cloud-based software, to monitor and control the flow of pallets within a supply chain.

System Description

The digitalised pallet system works by attaching RFID tags or IoT sensors to each pallet. These tags or sensors transmit data about the pallet’s location, condition, and contents to a centralised computer system. This data can be accessed in real-time through cloud-based software, allowing for accurate tracking and management of inventory.

The system also includes automated machinery, such as robotic forklifts and conveyor belts, which can move pallets around the warehouse based on instructions from the central computer system. This automation reduces the need for manual labour and increases efficiency.

Digitalised Supply Chain

In a digitalised supply chain, all stages of the supply process – from procurement of raw materials to delivery of finished goods – are connected through digital technology. This allows for real-time visibility and control over the entire supply chain.

In this context, a digitalised pallet system plays a crucial role in managing the physical flow of goods. By providing accurate, real-time data about each pallet’s location and status, it enables efficient planning and execution of supply chain activities.

Value Delivered for Customers

For customers, a digitalised pallet system offers several benefits. Firstly, it ensures accurate and timely delivery of goods. By tracking each pallet’s location in real-time, it eliminates the risk of lost or misplaced items.

Secondly, it improves product quality. The system can monitor conditions such as temperature and humidity, ensuring that goods are stored under optimal conditions. This is particularly important for perishable items like food or pharmaceuticals.

Finally, it enhances transparency. Customers can access the system’s data to track their orders in real-time, giving them confidence in the supply process.

Value Delivered for Shareholders

For shareholders, a digitalised pallet system delivers value by improving operational efficiency and reducing costs. The system’s automation reduces the need for manual labour, lowering labour costs. Its real-time tracking capabilities eliminate the risk of lost or misplaced items, reducing inventory costs.

Moreover, by improving product quality and customer satisfaction, the system can increase sales and boost the company’s reputation. This can lead to higher share prices and dividends, delivering financial returns for shareholders.

Summary

In conclusion, a digitalised pallet system is a powerful tool for managing and tracking the flow of goods in a supply chain. By leveraging digital technology and automation, it delivers significant benefits for customers and shareholders alike. It ensures accurate and timely delivery of goods, improves product quality, enhances transparency, reduces costs, and boosts operational efficiency. As such, it is an essential component of any modern supply chain.