Introduction: The Role of Industrial Gases in Driving Progress

Industrial gases play a crucial role in driving progress and innovation across various industries. These gases, such as oxygen, nitrogen, hydrogen, and carbon dioxide, are essential for a wide range of applications, from manufacturing and healthcare to food processing and energy production. They are used in processes that require controlled environments, precise temperature control, and chemical reactions. Without industrial gases, many industries would struggle to operate efficiently and effectively.

Understanding the Importance of Resource Management in Industrial Processes

Resource management is the efficient and effective utilization of resources in industrial processes. It involves optimizing the use of raw materials, energy, water, and other inputs to minimize waste and maximize productivity. Effective resource management is crucial for industries to remain competitive, reduce costs, and minimize their environmental impact.

One of the main challenges in resource management is balancing the need for resource efficiency with the need for productivity and profitability. Industries must find ways to reduce waste and conserve resources without compromising the quality or quantity of their output. This requires careful planning, monitoring, and continuous improvement.

However, effective resource management also offers significant benefits. It can lead to cost savings through reduced material and energy consumption. It can also improve operational efficiency by minimizing downtime and optimizing production processes. Additionally, resource management can help industries meet regulatory requirements and enhance their reputation as environmentally responsible organizations.

The Wide Range of Applications for Industrial Gases in Various Industries

Industrial gases have a wide range of applications across various industries. Let’s take a closer look at some of these industries and specific examples of how industrial gases are used:

1. Manufacturing Industry: Industrial gases are used in various manufacturing processes, such as metal fabrication, welding, heat treatment, and chemical synthesis. For example, oxygen is used in steelmaking to enhance combustion and increase productivity. Nitrogen is used for purging and inerting applications to prevent oxidation and maintain product quality. Hydrogen is used in the production of ammonia, methanol, and other chemicals.

2. Healthcare Industry: Industrial gases are essential in the healthcare industry for various applications. Oxygen is used for respiratory support and anesthesia. Nitrous oxide is used as an analgesic and anesthetic agent. Carbon dioxide is used in laparoscopic surgeries and as a contrast agent in medical imaging.

3. Food and Beverage Industry: Industrial gases play a crucial role in the food and beverage industry. Carbon dioxide is used for carbonation in soft drinks and beer production. Nitrogen is used for packaging to extend the shelf life of food products and prevent spoilage. Oxygen is used for modified atmosphere packaging to maintain product freshness.

4. Energy Industry: Industrial gases are used in the energy industry for various applications, such as power generation, fuel production, and carbon capture. Hydrogen is used as a fuel in fuel cells and can be produced from renewable sources for clean energy production. Carbon dioxide is captured and stored to reduce greenhouse gas emissions from power plants and industrial processes.

The Role of Industrial Gases in Enhancing Efficiency and Productivity

Industrial gases can significantly improve efficiency and productivity in manufacturing processes. Here are some ways in which industrial gases contribute to these improvements:

1. Enhanced Combustion: Oxygen-enriched combustion can significantly increase the efficiency of combustion processes, such as steelmaking, glass manufacturing, and waste incineration. By increasing the oxygen concentration in the combustion air, the fuel consumption can be reduced, leading to energy savings and lower emissions.

2. Heat Treatment: Industrial gases, such as nitrogen and hydrogen, are used in heat treatment processes to improve the mechanical properties of metals. These gases create controlled atmospheres that prevent oxidation and enable precise temperature control, resulting in improved product quality and reduced scrap rates.

3. Inerting and Purging: Inerting with nitrogen or carbon dioxide is commonly used in industries to prevent explosions, fires, and product degradation. By displacing oxygen or other reactive gases, inerting creates a safe environment for storage, transportation, and processing of flammable or sensitive materials.

4. Cryogenic Cooling: Industrial gases, such as liquid nitrogen and carbon dioxide, are used for cryogenic cooling in various applications, including food freezing, pharmaceutical manufacturing, and electronics production. Cryogenic cooling enables rapid cooling and freezing, which can improve production throughput and product quality.

Case studies and examples of successful implementation of industrial gases in manufacturing processes abound. For instance, a steel manufacturer implemented oxygen-enriched combustion in their reheating furnaces, resulting in a 20% reduction in fuel consumption and a significant decrease in greenhouse gas emissions. Another example is a food packaging company that implemented nitrogen purging to extend the shelf life of their products, reducing food waste and improving customer satisfaction.

Exploring the Environmental Benefits of Industrial Gases and Resource Management

Industrial gases and effective resource management can contribute to environmental sustainability in several ways:

1. Reduced Emissions: By optimizing processes and using industrial gases for combustion and inerting, industries can reduce greenhouse gas emissions and air pollutants. For example, oxygen-enriched combustion reduces fuel consumption and emissions of carbon dioxide and other pollutants. Inerting with nitrogen or carbon dioxide prevents the release of flammable or reactive gases into the atmosphere.

2. Waste Reduction: Effective resource management can minimize waste generation by optimizing material usage, recycling, and reusing resources. By implementing efficient processes and technologies, industries can reduce the amount of raw materials, energy, and water required for production. This not only reduces waste but also conserves natural resources.

3. Energy Efficiency: Industrial gases can improve energy efficiency by enabling more efficient combustion processes and heat transfer. For example, oxygen-enriched combustion reduces fuel consumption and increases the efficiency of heating furnaces. Cryogenic cooling with industrial gases can also improve energy efficiency in various applications, such as food freezing and electronics cooling.

4. Renewable Energy Production: Industrial gases, such as hydrogen, can be produced from renewable sources and used as a clean fuel for power generation and transportation. Hydrogen fuel cells offer a sustainable alternative to traditional combustion engines, as they produce only water vapor as a byproduct.

Innovations and Advancements in Industrial Gas Technologies

The industrial gas industry is constantly evolving, with new technologies and innovations driving progress and efficiency. Here are some of the latest advancements in industrial gas technologies:

1. On-Site Gas Generation: On-site gas generation systems allow industries to produce industrial gases on-demand, eliminating the need for storage, transportation, and handling of compressed or liquefied gases. These systems use advanced technologies, such as pressure swing adsorption (PSA) and membrane separation, to separate gases from air or other feedstocks.

2. Cryogenic Technologies: Cryogenic technologies, such as cryogenic distillation and liquefaction, enable the production and purification of industrial gases at extremely low temperatures. These technologies are used for large-scale production of gases like nitrogen, oxygen, and argon.

3. Carbon Capture and Utilization: Carbon capture and utilization (CCU) technologies capture carbon dioxide emissions from industrial processes and convert them into useful products. For example, carbon dioxide can be used as a feedstock for the production of chemicals, fuels, or building materials.

4. Advanced Gas Sensors: Advanced gas sensors enable real-time monitoring of gas concentrations in industrial processes. These sensors help ensure safety, optimize process control, and detect leaks or emissions.

These advancements in industrial gas technologies have significant implications for industries across various sectors. They offer opportunities for improved efficiency, reduced costs, and enhanced sustainability.

The Role of Industrial Gases in Promoting Sustainable Development

Industrial gases play a crucial role in promoting sustainable development and achieving the United Nations’ Sustainable Development Goals (SDGs). Here’s how industrial gases contribute to sustainable development:

1. Clean Energy Production: Industrial gases, such as hydrogen, can be produced from renewable sources and used as a clean fuel for power generation and transportation. Hydrogen fuel cells offer a sustainable alternative to traditional combustion engines, as they produce only water vapor as a byproduct.

2. Carbon Capture and Storage: Industrial gases, such as carbon dioxide, can be captured from industrial processes and stored underground to reduce greenhouse gas emissions. Carbon capture and storage (CCS) technologies are essential for achieving climate targets and mitigating the impacts of climate change.

3. Waste Reduction and Recycling: Effective resource management, including the use of industrial gases, can minimize waste generation and promote recycling. By optimizing processes and implementing circular economy principles, industries can reduce their environmental footprint and conserve natural resources.

4. Environmental Protection: Industrial gases, such as nitrogen and carbon dioxide, are used for environmental protection purposes, such as water treatment and air pollution control. Nitrogen is used for wastewater treatment to remove contaminants, while carbon dioxide is used for pH control in water treatment processes.

Case Studies: Real-world Examples of Industrial Gases and Resource Management Success Stories

Real-world examples demonstrate the significant improvements that can be achieved through the use of industrial gases and effective resource management. Here are two case studies that highlight the outcomes and benefits:

1. Steel Manufacturing: A steel manufacturer implemented oxygen-enriched combustion in their reheating furnaces to reduce fuel consumption and emissions. By increasing the oxygen concentration in the combustion air from 21% to 30%, they achieved a 20% reduction in fuel consumption, resulting in significant cost savings. The implementation also led to a decrease in greenhouse gas emissions by 15%, contributing to their sustainability goals.

2. Food Packaging: A food packaging company implemented nitrogen purging in their packaging process to extend the shelf life of their products. By replacing the oxygen in the packaging with nitrogen, they created a modified atmosphere that prevented spoilage and maintained product freshness. This resulted in a 30% reduction in food waste and improved customer satisfaction.

These case studies demonstrate the tangible benefits that can be achieved through the use of industrial gases and effective resource management. They highlight the potential for cost savings, improved product quality, and reduced environmental impact.

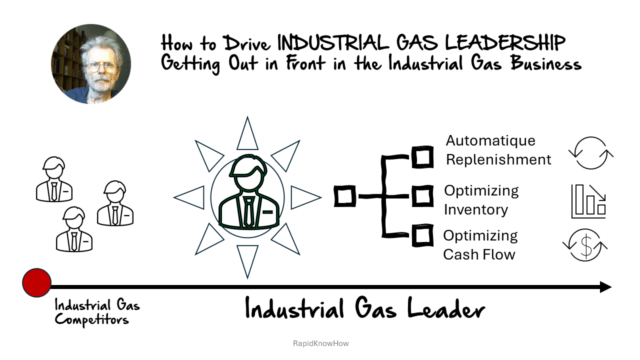

The Future of Industrial Gases: Trends and Opportunities

The industrial gas industry is poised for significant growth and innovation in the coming years. Here are some emerging trends and opportunities:

1. Hydrogen Economy: The transition to a hydrogen economy is gaining momentum, driven by the need for clean energy and decarbonization. Hydrogen is expected to play a crucial role in sectors such as transportation, power generation, and industrial processes. This presents opportunities for the industrial gas industry to expand hydrogen production, storage, and distribution infrastructure.

2. Carbon Capture and Utilization: Carbon capture and utilization (CCU) technologies are expected to play a vital role in reducing greenhouse gas emissions and achieving climate targets. The industrial gas industry can capitalize on this trend by developing advanced CCU technologies and providing carbon capture services to industries.

3. Digitalization and Automation: The digitalization of industrial processes, coupled with automation technologies, offers opportunities for improved efficiency, productivity, and safety. Industrial gas companies can leverage digital technologies, such as IoT sensors, data analytics, and artificial intelligence, to optimize their operations and provide value-added services to customers.

4. Circular Economy: The transition to a circular economy presents opportunities for industries to minimize waste generation, promote recycling, and conserve resources. Industrial gas companies can support this transition by providing solutions for resource management, such as on-site gas generation systems and waste treatment technologies.

Conclusion: Harnessing the Power of Industrial Gases for a Sustainable Future

Industrial gases play a vital role in driving progress, efficiency, and sustainability across various industries. They enable enhanced combustion, heat treatment, inerting, and cryogenic cooling, among other applications. Industrial gases also contribute to environmental sustainability by reducing emissions, minimizing waste, and promoting renewable energy production.

Effective resource management is crucial for industries to optimize their processes, reduce costs, and minimize their environmental impact. By implementing resource-efficient practices and technologies, industries can achieve significant improvements in efficiency, productivity, and sustainability.

The future of the industrial gas industry is promising, with emerging trends such as the hydrogen economy, carbon capture and utilization, digitalization, and the circular economy. These trends present opportunities for growth, innovation, and collaboration across industries.

In conclusion, harnessing the power of industrial gases and embracing effective resource management is essential for industries to drive progress and achieve a sustainable future. By leveraging the benefits of industrial gases and adopting resource-efficient practices, industries can enhance their competitiveness, reduce their environmental footprint, and contribute to a more sustainable world. It is crucial for industries to embrace these opportunities and work towards a sustainable future.