Every time you reduce industrial gas use, you reduce cost and exposure to liabilities.

Beyond tangible expenditures, there are not so quantifiable benefits to well-managed total cost ownership programs:

- Reduced accidents

- Maintaining a good reputation in the community

- Staying clear of environmental agencies’ spotlights etc.

[emaillocker id=”9547″]

Stakeholders are paying attention to the environmental, safety and health impact of companies.

Savvy companies start optimizing safety, health, environmental and total cost ownership of the entire industrial gas supply chain.

How to get started?

To execute this in practice you’ll need a proven, practical process.

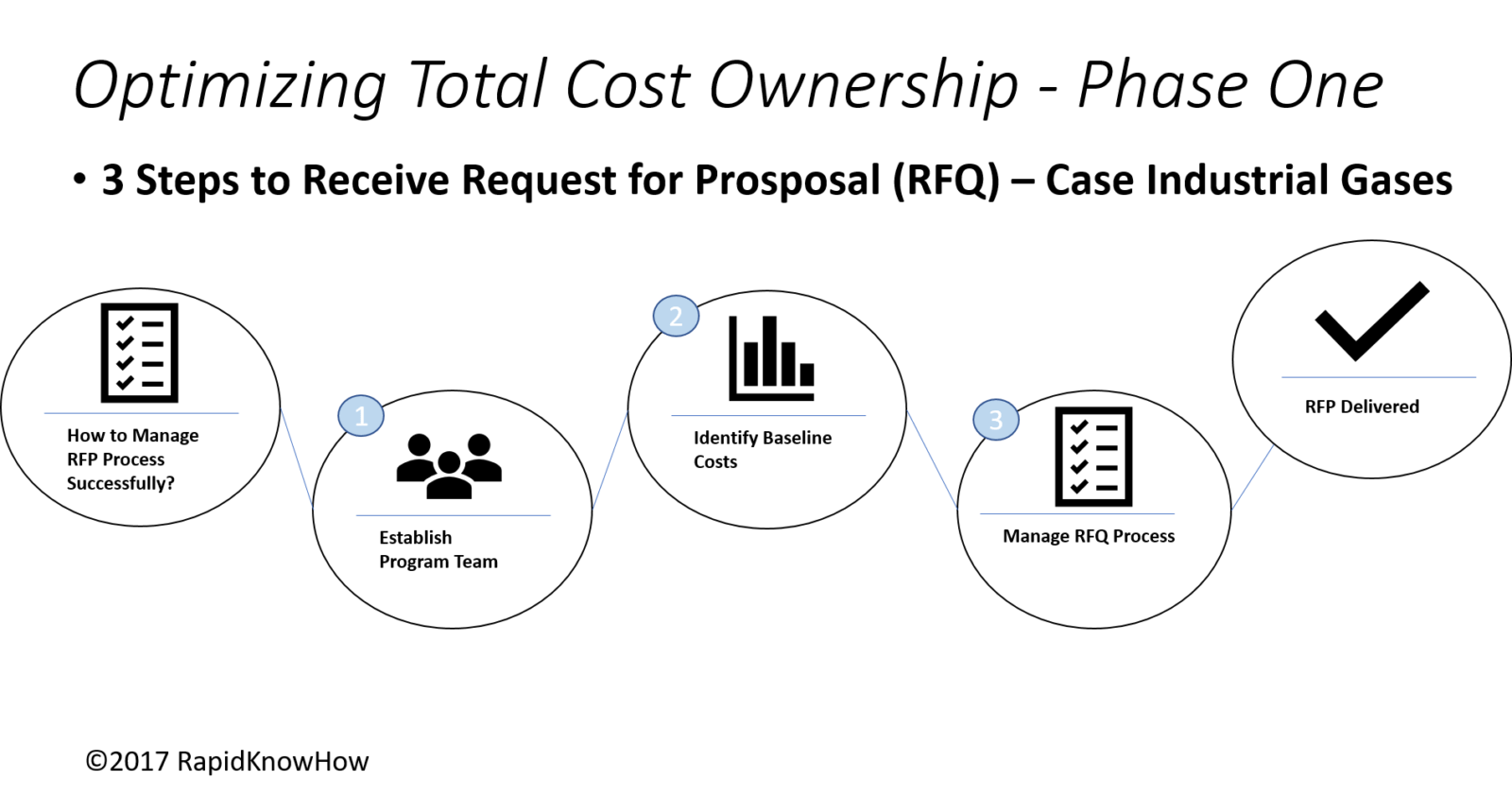

Here is our proven 3-step process to receive RFP from would be industrial gas service providers rapidly

Step 1 Establish Program Team

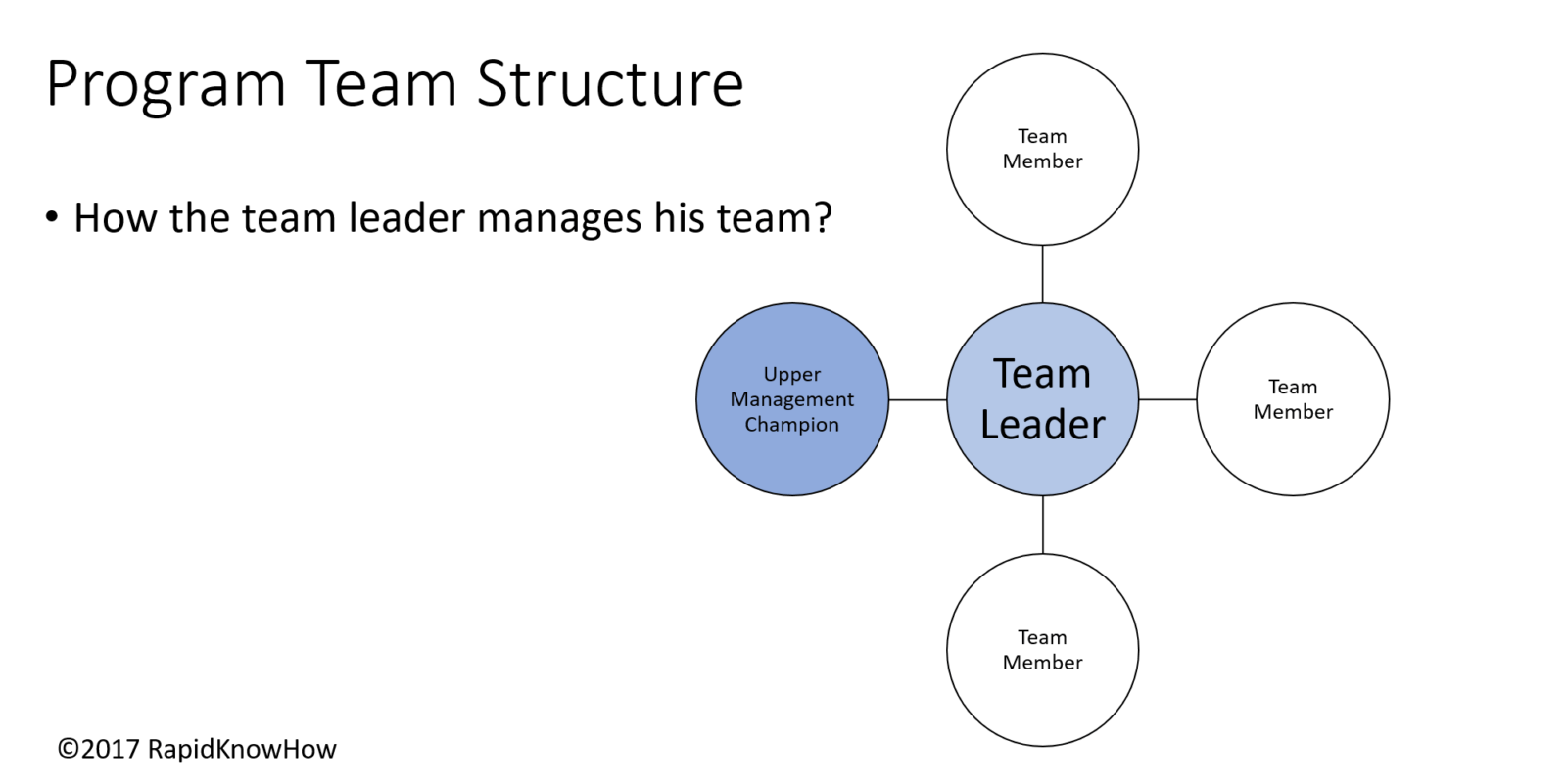

The first step is identifying a team leader charged with development and leading the program.

The leader must have an intimate knowledge of the facility and industrial gas management systems, be influential with upper management and his/her peers; and have strong leadership and communication skills. (see graphic)

Next the team leader will define team roles and responsibilities.

The team will develop goals and objective:

- Reduce total cost of industrial gas supply

- Improve production quality and efficiency

- Using know-how of industrial gas suppliers (logistics, application, safety, health and environment, liability)

Step 2 Identify Baseline Costs

The team’s first task is to identify baseline costs of industrial gas supply.

You’ll select a facility and start documenting industrial gas use.

The goal is to generate a list of industrial gas used in the last 12 months and their volumes.

Industrial Gas Consumption last 12 month (in tsd m3/t)

| Gases | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Oxygen | 100 | 110 | 120 | 125 | 130 | 135 | 140 | 110 | 100 | 90 | 80 | 70 |

| Acetylene | 50 | 52 | 55 | 54 | 55 | 40 | 55 | 45 | 40 | 30 | 25 | 35 |

| Ar-Mix | 20 | 30 | 35 | 40 | 60 | 65 | 70 | 20 | 25 | 23 | 22 | 23 |

Next, your team will document industrial gas purchase costs.

The purchasing department will provide the unit prices of gases and related services (cylinder rents, tank rents, manifold rents etc.)

The value of this documentation is that it provides a baseline for measuring future price reductions when consolidating your entire industrial gas purchase.

Step 3 Manage RFP Process Successfully

Next, you’ll present your findings to the top management champion or steering group to determine portion of the industrial gas supply chain should be transferred to an industrial gas service provider.

Choose from these 5 Supply Chain Sub Processes: Procure > Inspection > Inventory > Use > EHS

Next the team will develop a request for proposal (RFP).

The request for proposal is developed from your team’s original objectives, baseline data, required scope of services and industrial gases.

A TCO service provider (bidder) will need sufficient information about your objectives, needs, and specified scope of services to accurately estimate the industrial gas service costs.

Elements of an RFP

We found the broad elements to be essential in clearly and systematically describing your industrial gas service requirements:

- Cover Letter

- Introduction

- Scope of Services

- Scope of Industrial Gases

- Performance Metrics

- Compensation and Incentives

Develop a List of Suppliers

With the text of the RFP complete, your task will shift to determining who should receive the RFP.

Begin your list by naming current suppliers with whom you have had positive experiences.

These three criteria will help you narrow your list:

- Experience providing industrial gas services that optimize entire supply chain costs

- Capability of assuming liability for stock-outs

- Multi-regional presence if you want standardized services across geographical areas and business segments.

Inform key facility personnel that an RFP will be released

Through your earlier communications, you have already informed people affected by the new program of the team’s progress.

Once the RFPs are distributed, however, its public knowledge that your company has intentions of significantly changing your industrial gas management operations.

Therefore, it is important to inform a broader circle of people within your company that they may be receiving inquiries about the RFP. Facility personnel should direct all inquiries to the team-designated point person.

Convene a Bidders Conference

One challenge in managing the RFP process is ensuring that all bidders are provided the same information.

The agenda for the conference should be flexible and include:

- Introduction

- Industrial Gas Service Provider Program Goals & Purpose

- Company & Facility Overview

- Facility Tour

- RFP Discussion and Q&A

– General

– Scope Elements

– Compensation

– Concluding Remarks and Restatement of Schedule

Receive Proposals and Send Out Conformation of Receipt

As you receive proposals, you should carefully log what you have received and scan the proposals for completeness.

For each RFP recipient, you should send a written communication following the proposal submission deadline.

Use these simple letter formats:

Thank you for your proposal. We will contact you on __________

We have received your proposal and found it to be incomplete in the following areas: ___________________

We have not received a proposal from you.

Please let us know if you plan to submit one or, if not, why you chose not to submit one.

Once you have received all the proposals, you’re ready to begin the difficult task of evaluating them.

The challenges at this stage are to evaluate each proposal on the same basis and to determine if the response is credible.

Ask the critical question:

How likely is It that the bidder can support the response in practice?

After analysing the costs and benefits of the proposals, you’ll start selecting your primary industrial gas service provider.

Next we’ll learn how to select a primary service provider.

[/emaillocker]