Learn the non-cryogenic air separation process that drives cost efficiency in one hour

The cryogenic process is very power intensive, and so over the past 50 years, companies have developed a lower power consuming process to separate air. There are two forms of commercially available non-cryogenic air separation technologies which have been developed over the last 30 years and which now provide cost-effective solutions under certain limited circumstances

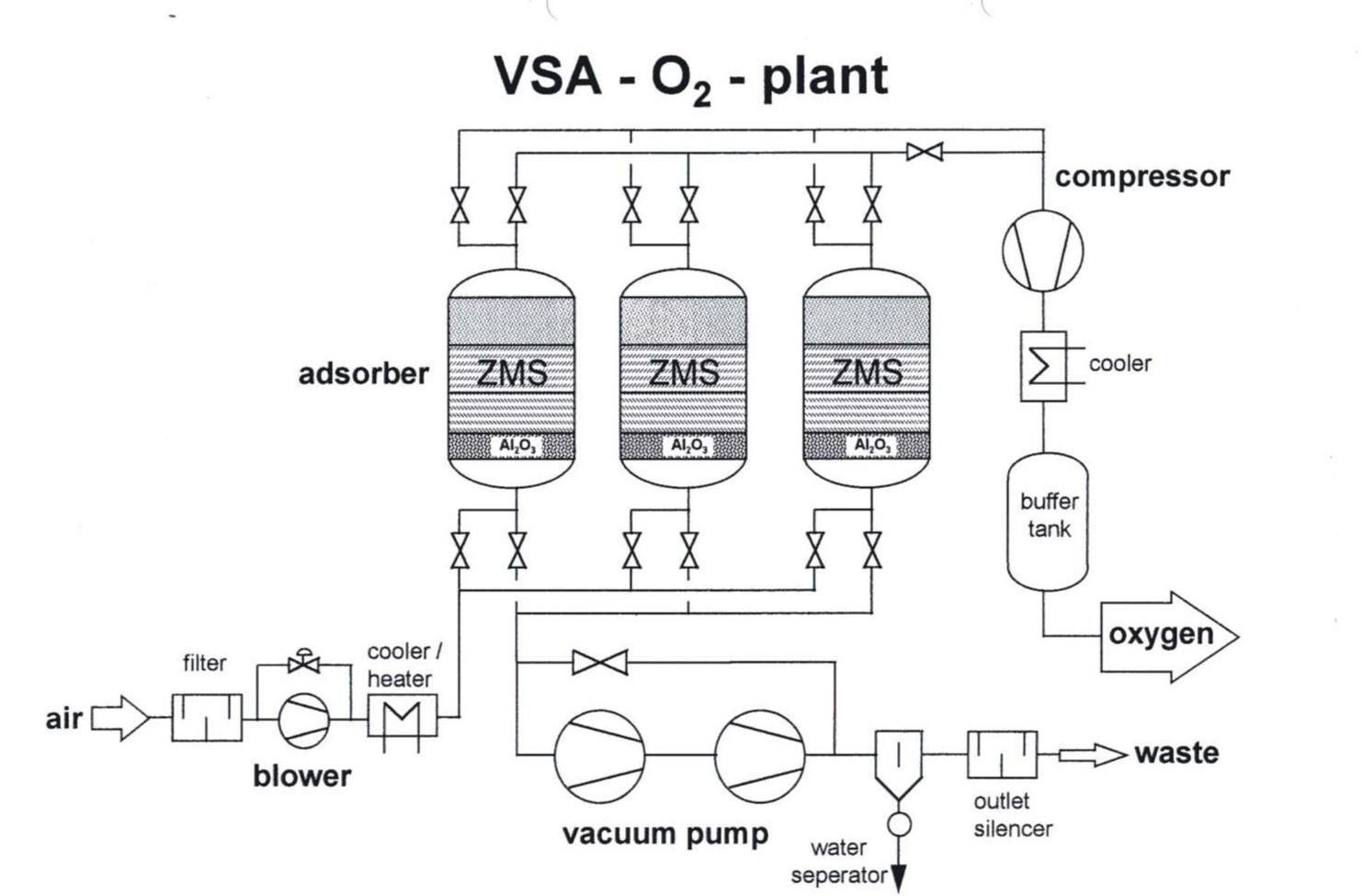

Pressure Swing Adsorption (PSA) and Vacuum Swing Adsorption (VSA)

Pressure swing adsorption (PSA), or VSA (where the vacuum is employed) utilise the differential adsorption rate of oxygen and nitrogen by a molecular sieve material (carbon for nitrogen, zeolite for oxygen). They can be used to economically produce oxygen or nitrogen (but not both together) of lower purity (circa 93-98%) in gaseous form only for quantities up to about 100 tpd.

[emaillocker id=”9547″]

A PSA or VSA unit consists of two or more low-pressure vessels to hold the molecular sieve, interconnecting pipe-work and switching valves operated by a programmable solid-state controller and an air blower/compressor for the air feed. (VSA also includes a vacuum pump).

The vessels holding the sieve are pressurised and de-pressurised according to pre-set cycles.

There can also be a buffer storage vessel for the oxygen or nitrogen produced, which is usually at a few atmospheres pressure. Higher purity is gained at the expense of throughput.

Figure 1 shows a basic layout of a PSA system (Oxygen)

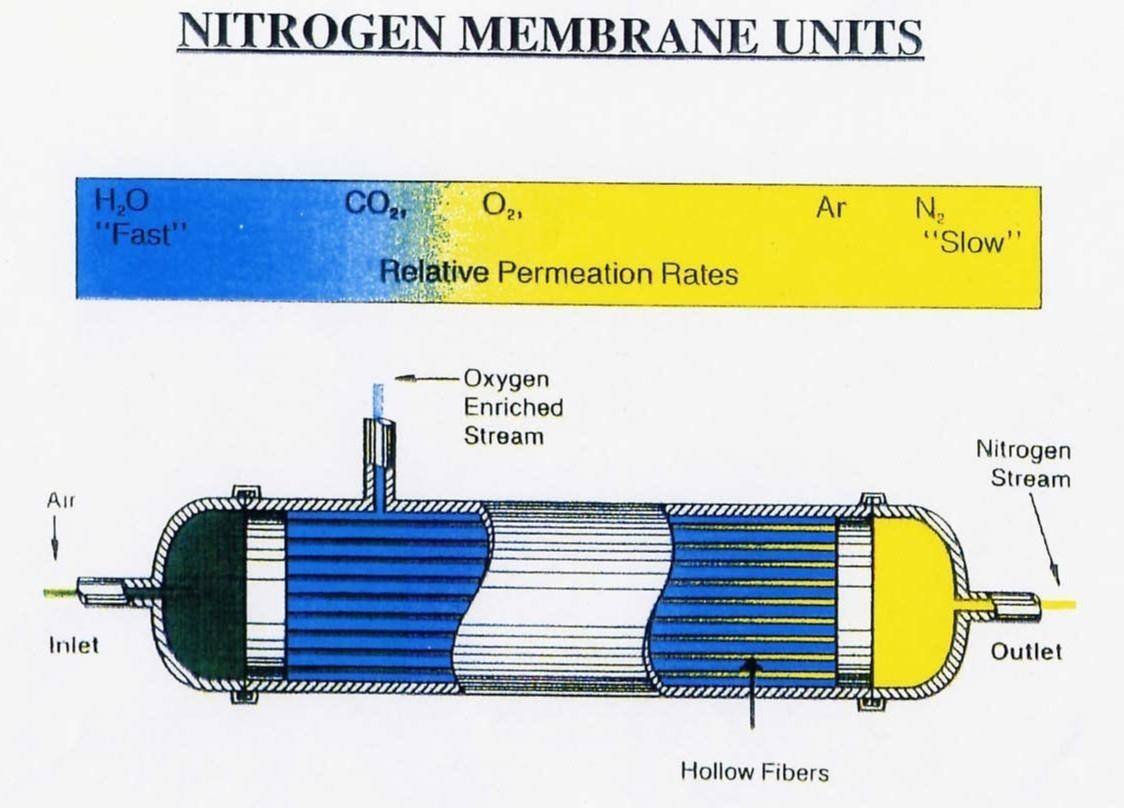

Membrane

Membrane methods, which pass the air through thin hollow polymer fibres whose walls act as semipermeable membranes and allow the oxygen to permeate through.

They can be used to produce (circa 95-99% purity) nitrogen in gaseous form in small quantities (but many units can be connected in parallel).

A membrane “unit” usually consists of a number of modules holding the membrane fibres connected to a low-pressure air blower which operates continuously rather than cycling as in PSA/VSA.

It is even simpler to operate than a nitrogen PSA unit but of somewhat lower purity output.

These non-cryogenic technologies are much simpler to operate than the cryogenic ASU method. Regarding power consumption per unit of output (specific power), they can be competitive with smaller ASUs for lower purity gas.

However, they do not exhibit the same economies of scale as ASUs since the major cost components are the sieve or membrane, the amount of which is directly proportional to the plant capacity.

Consequently, they are currently confined to smaller supply situations or particular situations such as sea-going or offshore installations.

Whereas the cryogenic technology is “mature”, these non-cryogenic technologies are still undergoing continual development and pushing out the boundaries of which they can be cost-effective.

Figure 2 presents a schematic of a membrane unit

Applicability of Non-Cryogenic Technology

Applicability of Non-Cryogenic Technology

In practice, the impact of these alternative technologies on the business of the industrial gas companies has been wholly favourable.

Nearly all installations are owned by industrial gas companies or supplied and serviced by them

The reason is that most users want a reliable supply of gas and therefore need assured backup supplies, usually of liquid nitrogen or oxygen that can be vaporised to maintain supply when the production plant fails.

A number of large “blue-chip” corporations have tried to enter the industrial gas business and have eventually sold out to industrial gas companies, because of the inability of the new entrants to provide back up and the natural unwillingness of the industrial gas companies to support them.

Smaller companies have tried to break into niche markets for small volume users based on the smaller companies lower overhead cost position. In the end, these too have been acquired by or formed alliances with industrial gas companies. The industrial gas companies have been pro-active in converting any vulnerable liquid accounts to small gas-supply accounts.

There are enough potential suppliers of such technology, that any industrial gas

company can access it and use it when required. The position for oxygen noncryogenic production is similar, with a further limitation that it is only competitive at purities below about 93% oxygen.

[/emaillocker]

[email-subscribers namefield=”YES” desc=”Subscribe to RapidKnowHow and Get New Posts Delivered to Your Email Box” group=”Public”]